Main areas of application for polymer materials:

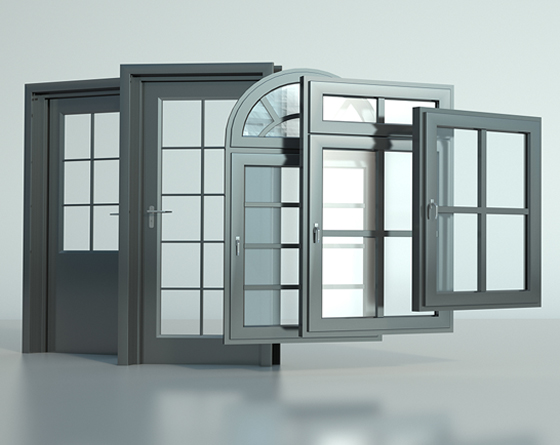

Construction and finishing (window and door profiles, flooring, cladding panels),

Packaging and containers (bags and films, canisters, bottles, disposable tableware),

Furniture, toys, and more.

We conduct testing of various polymer materials:

- Rubber sealing gaskets according to DSTU B V.2.7-242:2010, DSTU B V.2.7-293:2011

- Rubber products according to DSTU ISO 6916-1:2009

- Polyvinyl chloride (PVC) profiles according to DSTU EN 12608-1:2021, DSTU B V.2.7-130:2007

- Polyvinyl chloride (PVC) linoleum according to DSTU B V.2.7-20-95, DSTU B V.2.7-21:2013

- Packaging made of polymer and composite materials according to DSTU 7275:2012

- Plastic barrels and canisters according to DSTU EN 12707:2006, DSTU EN 12709:2006, DSTU EN 12714:2005, DSTU EN 12712:2005

Clients who request polymer material testing receive a number of important advantages and information that help them make informed decisions and ensure the quality of their products or projects. Here are the main results they obtain:

Objective data on material properties: Testing protocols provide accurate and quantitative data on the physical, mechanical, chemical, thermal, and other important characteristics of polymer materials. This includes indicators such as tensile strength, impact resistance, hardness, thermal resistance, chemical resistance to specific substances, and more.

Assessment of material quality and reliability: Testing helps assess the quality of a batch of material and identify possible defects or deviations from declared characteristics. This prevents the use of substandard raw materials or components in production, which could otherwise lead to a reduction in the quality of final products or accidents.

Optimization of production processes: Test results can provide information necessary for optimizing polymer processing technologies, such as injection molding, extrusion, or forming modes.

Risk reduction and cost prevention: Using materials that have successfully passed testing reduces the risk of quality issues in the final product, warranty claims, product returns, and other associated costs.

Confirmation of compliance with standards and technical specifications: Testing results show whether the examined polymer material meets the requirements of national or international standards (such as ISO, ASTM, DSTU), industry norms, or the customer’s technical specifications. This is particularly important for quality control and product certification.